The manufacturing industry constantly seeks efficiency and quality. One significant innovation is the Offset Inline Inspection System. This technology enhances quality control in production lines.

An Offset Inline Inspection System aims to detect defects in real-time. It operates seamlessly during the manufacturing process, ensuring products meet standards. This system can minimize delays in production, leading to enhanced productivity.

However, like any technology, it has limitations. The accuracy of detection can vary depending on the conditions. Operators must regularly calibrate the system to maintain precision. Reflecting on these challenges can foster improvements in the implementation of such systems.

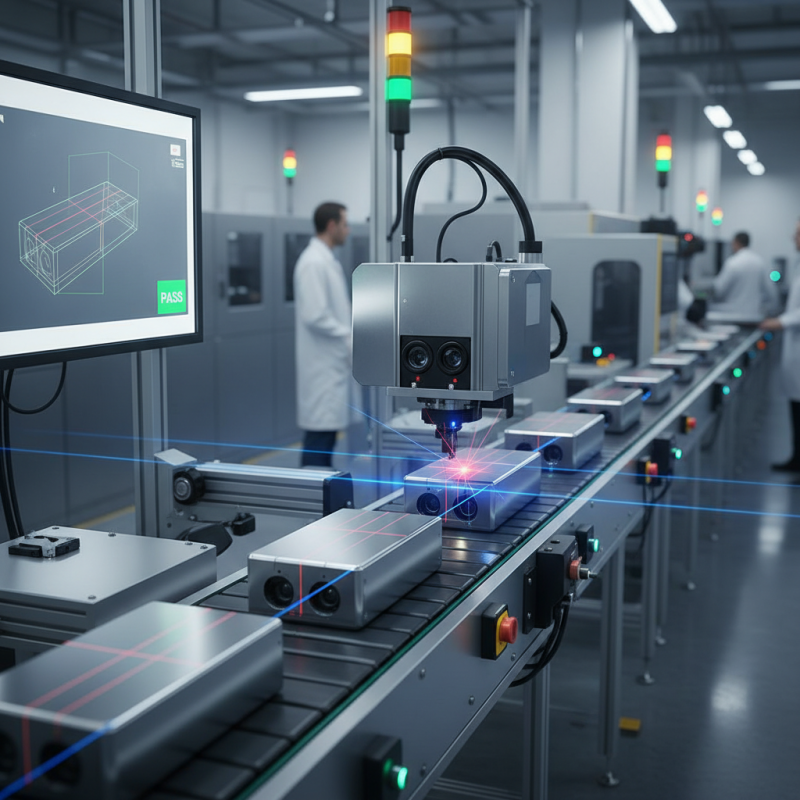

An Offset Inline Inspection System is a technology used to monitor and evaluate products during the manufacturing process. It operates by assessing items as they move along a production line, allowing immediate detection of defects. This system is particularly useful in industries like food, pharmaceuticals, and electronics.

The process involves sensors and cameras that capture images of the products. These devices assess various parameters such as size, shape, and color. If a defect is detected, the system can alert operators instantly. This feature helps reduce waste and improve quality control. However, the initial setup can be complex. Integrating the system with existing machinery requires careful planning and investment.

Despite its advantages, the system may produce false positives. Sometimes, good products are flagged as defective. This can lead to unnecessary rework and increased costs. Regular calibration and maintenance are crucial to minimize these issues. Continuous training for operators is essential to ensure the system functions optimally. Thus, while an Offset Inline Inspection System offers significant benefits, it also presents challenges that need addressing.

Offset Inline Inspection Systems are essential in modern manufacturing processes. They ensure product quality and process efficiency. These systems utilize advanced sensors and imaging technology for real-time monitoring.

Key components of these systems include high-resolution cameras, illumination devices, and integrated software. High-resolution cameras capture detailed images of products, allowing for precise defect identification. Illumination devices enhance image quality, reducing shadows that might obscure defects. The software analyzes images, providing insights into product consistency and performance.

Research indicates that implementing these systems can reduce defect rates by up to 30%, leading to significant cost savings.

Tip: Regular calibration of sensors is critical to maintain accuracy. Ensuring proper lighting conditions can enhance inspection quality. When implementing these systems, consider potential distractions that may lower inspection effectiveness. Relying solely on technology without proper oversight might lead to oversight of subtle defects. Engaging staff in the inspection process can yield better results.

Offset Inline Inspection Systems play a crucial role across various industries. These systems inspect products seamlessly during the manufacturing process. According to a recent report by the International Society for Automation, 65% of manufacturers now use such systems to enhance quality control and reduce waste. They can detect defects in real-time. This minimizes the risk of faulty products reaching customers.

Automotive industries rely heavily on these systems. The ability to identify issues instantly can save millions in recalls. A 2022 study revealed that about 30% of automotive defects could be caught with effective inline inspections. However, imperfect setups can lead to false positives. This creates delays and costs money. It's a balance between speed and accuracy that still needs fine-tuning.

In packaging, offset inline inspection systems are increasingly critical. They ensure that labels and seals are correct. A report from Packaging World highlighted that 75% of packaging errors occur without proper inspection. Yet, many systems lack comprehensive software integrations. This limits their effectiveness. Companies must consider these factors to improve operational efficiency and product integrity.

Offset Inline Inspection Systems (OIS) are gaining traction in manufacturing for several reasons. One significant advantage is their ability to ensure product quality in real-time. According to a report by the Quality Assurance Institute, companies that implement OIS see a 30% reduction in defects. This leads to significant cost savings and boosts customer satisfaction.

Moreover, OIS systems are designed to seamlessly integrate with existing production lines. This reduces downtime during inspections. In some cases, manufacturers have reported a 20% increase in production efficiency. However, implementing these systems isn't without challenges. Some organizations struggle with employee training and operational adjustments. These factors can lead to temporary inefficiencies.

Additionally, the data collected through OIS can provide valuable insights. A study by the Manufacturing Research Group indicated that 75% of companies using real-time data analytics improve their decision-making processes. Yet, many firms may underutilize this data, which limits their potential benefits. Addressing these challenges is essential for maximizing the advantages of Offset Inline Inspection Systems.

This bar chart represents the performance metrics of Offset Inline Inspection Systems, showcasing their Speed, Accuracy, Cost Efficiency, Flexibility, and User Satisfaction with scores out of 100. The high levels of user satisfaction and accuracy indicate the effectiveness of these systems in various industrial applications.

Implementing Offset Inline Inspection Systems presents various challenges. One key issue is the integration with existing production lines. Many facilities have legacy systems that are not easily compatible. This can lead to increased costs and longer installation times. In fact, a survey indicated that 45% of companies experienced delays due to integration issues.

Data accuracy is another concern. While these systems promise real-time insights, the quality of data collected can vary. A recent report showed that 30% of inspection systems failed to meet accuracy standards. This raises questions about reliability. Are we relying too much on automated data?

Training staff is critical. Workers must understand the technology and how to interpret results. However, 60% of companies reported difficulties in training existing employees. This knowledge gap can lead to underutilization of inspection systems. Without skilled personnel, the full potential of these technologies may not be realized. The balance between automation and human oversight remains delicate and challenging.